-

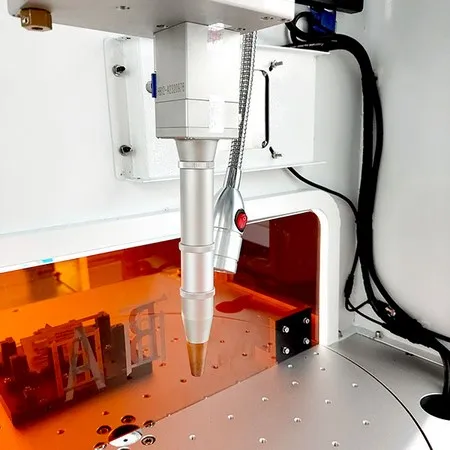

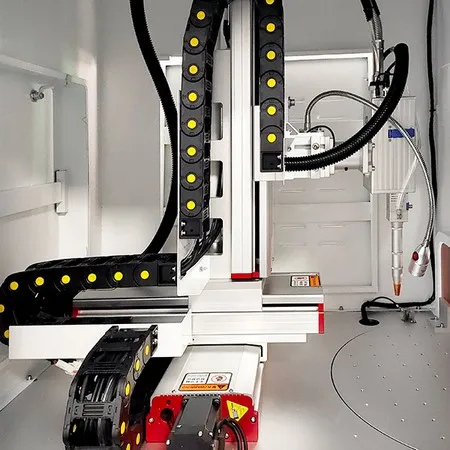

Multi-Axis Double-Station Laser Welding Machine

The multi-axis double-station laser welding machine offers a fast and precise solution for joining two different metals. Using oscillation welding, it delivers high-quality beam control, making it perfect for precise spot welding of various components. The double station laser welder allows for customizable welding patterns such as straight lines, rectangles, circles, figure eights, and spirals, with a maximum oscillation amplitude of 5mm.

Multi-axis laser welders are suitable for a wide range of industries, including mobile phones, communications, steel, microelectronics, high-end digital components, and medical devices. It can weld various materials, such as carbon steel, alloy steel, and stainless steel. Additionally, it excels at welding different types of metals together, such as stainless steel to low-carbon steel, 416 stainless steel to 310 stainless steel, 347 stainless steel to HASTELLOY nickel alloy, nickel electrodes to cold-forged steel, copper to nickel, nickel to titanium, copper to titanium, titanium to molybdenum, brass to copper, and low-carbon steel to steel.

- Equipped with a laser source, oscillating welding head, industrial control system, cooling system, laser control system, and a high-precision modular cabinet

- Specialized laser welding software based on the Windows platform allows users to input and edit welding points or patterns directly within the software or import designs from other software

- The dual workstations enhance productivity by allowing simultaneous processing of different tasks, ideal for high-volume production environments

- Ensures accurate and high-quality welding for intricate components and challenging tasks, providing stable performance and easy operation

| Model | CC-HJ1500W |

| Laser wavelength | 1064nm |

| Laser power | 1000W, 1500W, 2000W |

| Standard welding area | 500*400mm |

| Min. spot size | 0.1mm |

| Min. character | English: 0.15*0.15mm |

| Repeat accuracy | +0.005mm |

| Welding speed | ≤200mm/s |

| Power supply | AC220V±10%,50Hz |

| Total power | 3000W |

| Cooling method | Water cooling |

| Working conditions | Temperature: 1-35℃ Humidity: 5%-80% (non-condensing) |

Curious About Our Laser Systems?

Contact us to request a quotation, technical specifications & more!

- Luo Meilian (Manager)

Building 2, Yonghui Science and Technology Park, Hengli Town, Dongguan City, Guangdong Province, China